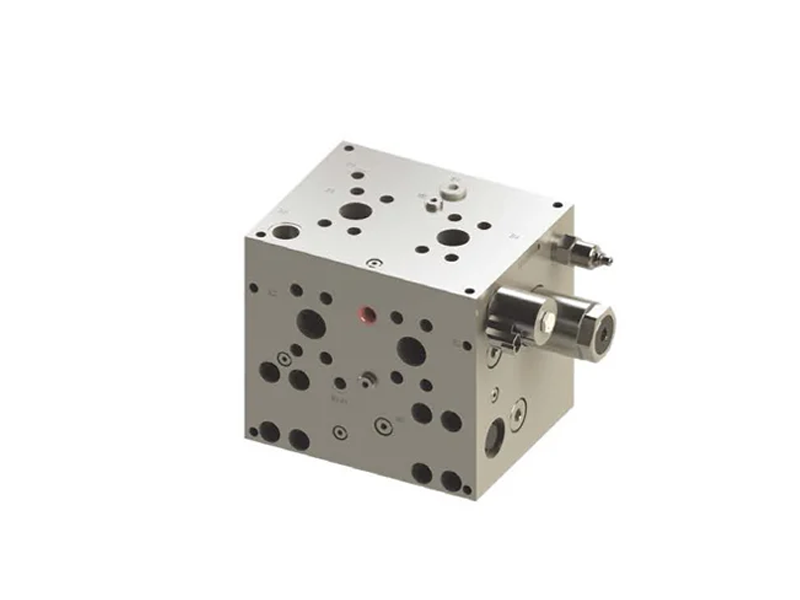

Winch balancing valve RT-VBM0004

- Maximum pressure : 350 bar

- Max. flow rate: 600L/min

- Relief valve set pressure: 420bar@2.5L/min

- Typical application: winch system

Product Overview

The RT-VBM0004 winch balancing valve is primarily used in winch systems to control the raising and lowering of loads. It performs dual functions of load retention and speed control during the winch’s descent. A damping function is incorporated into the control port to control oil flow rate and absorb vibrations. It also allows the load to float and transmits signal oil to the winch system’s brake system via a shuttle valve during both descent and ascent.

Technical Parameters

| Technical Parameters | |

| Work pressure | B1≤420bar、B3≤350bar、A≤350bar |

| Rated flow | 600L/min |

| Solenoid valve voltage | 28VDC±10% |

| Relief valve set pressure | 420bar@2.5L/min |

| Working ambient temperature | -20-90℃ |

Working principle and technical features

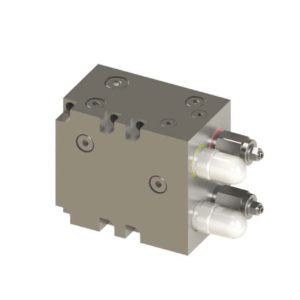

When the load rises, pressure oil flows from port B3 to port A2, opening the check valve.

When the load descends, pressure oil flows from port A2 to port B3, opening the counterbalance valve. When pressure oil flows from port B3 to port A2, the solenoid valve switches on and off to cause the load to float, while the throttle valve adjusts the floating speed. The shuttle valve primarily transmits signal oil to the brake system in the winch system.

Technical Features:

· Cone valve structure and line seal ensure low leakage.

· A damping bridge is installed in the pilot oil circuit to ensure stable and shock-free pilot oil pressure.

· A relief valve is connected in parallel with the main oil circuit to independently adjust system pressure, ensuring equipment safety.