As the “nerve center” of hydraulic servo systems, electro-hydraulic servo valves directly determine the operational stability, control precision, and overall performance of industrial equipment. Whether you’re designing a position control system or optimizing a force regulation setup, selecting the right servo valve is a critical step that balances performance, cost-effectiveness, and reliability. At Radk Hydro, we simplify this process by aligning our diverse product portfolio with your specific application needs.

Key Factors in Electro-hydraulic Servo Valve Selection

A successful selection process hinges on evaluating factors that match the valve to your system’s unique demands. Core considerations include:

- Performance & Specifications: Dynamic response speed, control precision, and anti-interference capabilities

- Reliability & Durability: Operational stability, contamination resistance, and service life

- System Compatibility: Working fluid (oil type), oil source parameters, and electrical performance (matching with amplifiers)

- Practicality: Mounting structure, dimensional constraints, and cost-effectiveness

Application-driven Selection: The Radk Hydro Approach

Radk Hydro classifies its electro-hydraulic servo valves into general-purpose and special-purpose categories, enabling quick matching with your application scenarios—eliminating the complexity of redundant parameter comparisons.

Special-purpose Servo Valves: Tailored to Unique Challenges

When standard solutions fall short, our customizable special-purpose valves rise to the occasion. We tailor every detail to your requirements, including special valve openings, overlap configurations, linear gains, and spool positions (for zero-control-signal states). Our engineered solutions excel in extreme or specialized environments such as:

- Special working media (blue oil, fuel oil)

- Highly contaminated or high-temperature oil systems

- Vibration-intensive or high-acceleration setups

- Harsh conditions (mold, corrosion, electromagnetic interference)

- Hazardous environments (explosion-proof requirements)

- Diving or underwater applications

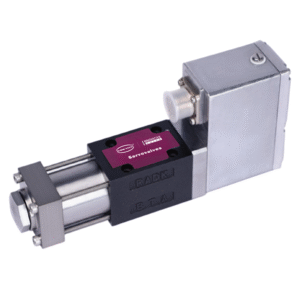

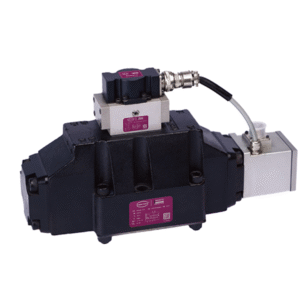

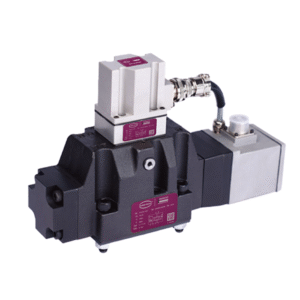

General-purpose Servo Valves: Versatile, Cost-effective, and Reliable

As our most widely used and mass-produced products, Radk Hydro’s general-purpose servo valves cover three core types, each optimized for specific control tasks:

| Valve Type | Key Advantages | Ideal Applications |

| General-purpose Flow Servo Valves | Linear pressure gain via pressure negative feedback; stable performance | Position control systems; open/closed-loop force control systems |

| General-purpose Pressure Servo Valves | Precise pressure regulation; optimized for force control scenarios | Force/pressure control systems; low-dynamic-demand setups |

| General-purpose Pressure-Flow Servo Valves | Dual linear gain (flow + pressure); eliminates redundant force/torque | High static/dynamic precision systems; combined position-force control; passively loaded systems |

Matching Precision to Cost: Choosing the Right Performance Level

Not every system requires top-tier performance—and we help you avoid over-engineering. For applications with moderate control accuracy or low dynamic demands, our industrial-grade servo valves offer exceptional value. Reserve our high-performance models for systems requiring superior precision; while they command a premium, their reliability and performance justify the investment.

Simplify Your Selection with Radk Hydro

The right electro-hydraulic servo valve doesn’t just meet specifications—it simplifies system design, reduces energy waste, and eliminates the need for costly workarounds (such as electrical compensation or oversized valves). Whether you need a standard general-purpose valve or a fully customized solution, Radk Hydro’s expertise ensures a perfect match for your application. Contact our technical team today to discuss your requirements.

Facebook

Twitter

LinkedIn