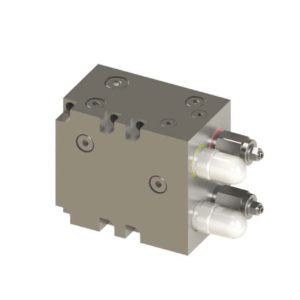

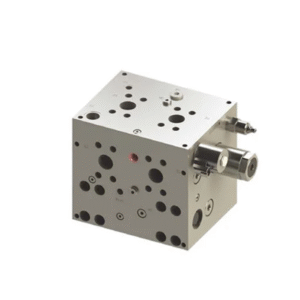

Product Overview

Primarily applied in roadheader hydraulic cylinder circuits, it provides safety protection and load maintenance for stable equipment operation.

- Target scenario: Used in roadheader lifting and rotating cylinders, which endure alternating impact loads during coal/rock cutting.

- Core function: Regulates the inflow and outflow of pressurized oil in cylinders to realize dynamic and static control.

- Eliminates the impact of cylinder movement on the hydraulic system.

- Reduces machine body vibration.

- Effectively enhances the safety and stability of roadheader operations.

Technical Parameters

|

Hydraulic Parameters |

|

Max. working pressure |

270bar |

|

Rated flow |

90L/min |

|

Relief valve set pressure |

200~350bar |

|

Pilot ratio |

4:1 |

|

Leakage |

≤0.3ml/min |

Working principle

Simplified operational logic based on mechanism action, focusing on oil flow direction and control port function.

- Oil flow: Flows freely from A1→B1 or A2→B2.

- Reverse flow: Blocked to prevent unintended movement.

- Basic oil flow direction: B1→A1.

- Control port role: A2 serves as the control port.

- Input control oil to A2: Opens the balancing valve port.

- Result: Load pressure oil flows smoothly from B1→A1.

- Ultra-low internal leakage: Poppet valve structure + wire seal keeps leakage < 0.3 ml/min.

- Fast & easy installation: Integrated threaded cartridge design reduces on-site setup time.

- Strong load adaptability: 4:1 pilot ratio handles varying load conditions.