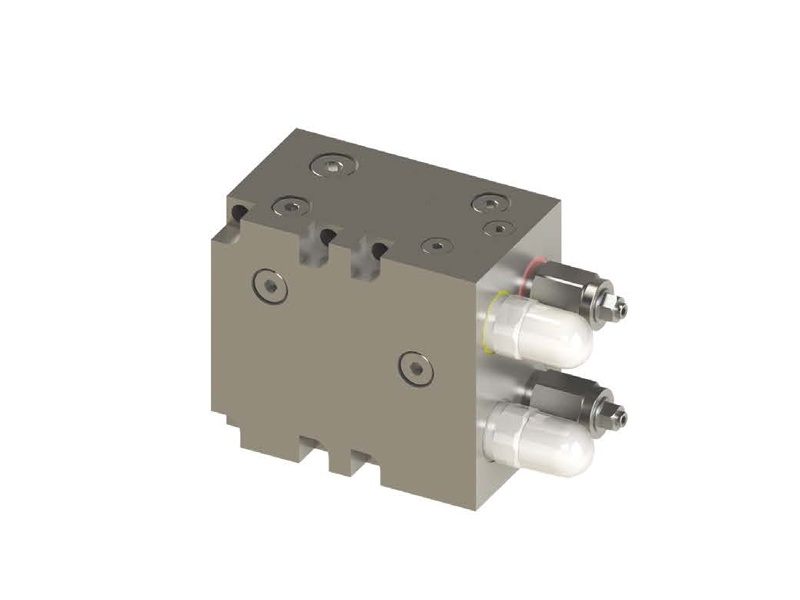

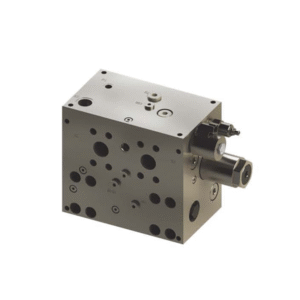

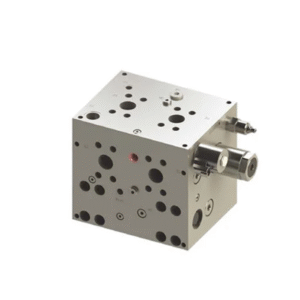

Product Overview

Primarily installed in roadheader hydraulic cylinder circuits, these valves serve two core purposes: safety protection and load maintenance.

- Balance external loads: Create backpressure to offset external load weight.

- Stabilize load movement: Maintain and control stability when lowering loads, prevent vibration.

- Ensure machine operation: Guarantee smooth running of the main roadheader.

Technical Parameters

|

RTHVB0024 Hydraulic Parameters |

|

Balance valve opening pressure |

350bar |

|

Relief valve set pressure |

200~350bar |

|

Rated flow |

90L/min |

|

Maximum pressure of relief valve |

400bar |

|

Leakage |

≤0.3ml/min |

|

Fluid temperature |

-20~90℃ |

Working principle

-

- Mechanism raising/extending

- Oil flows freely: A1→B1 or A2→B2 (reverse flow blocked).

- Safety protection: Load relief valve parallels pressure oil circuit to limit maximum system pressure.

- Mechanism lowering/retracting

Technical Features

- Ultra-low internal leakage: Cone valve structure + wire seal keeps leakage < 0.3 ml/min.

- Easy & quick installation: Integral threaded cartridge design reduces on-site installation time.

- Load adaptability & pressure control: 4:1 pilot ratio handles changing loads; parallel overflow valve adjusts system pressure independently for safety.